Progress for this week:

Controls Team:

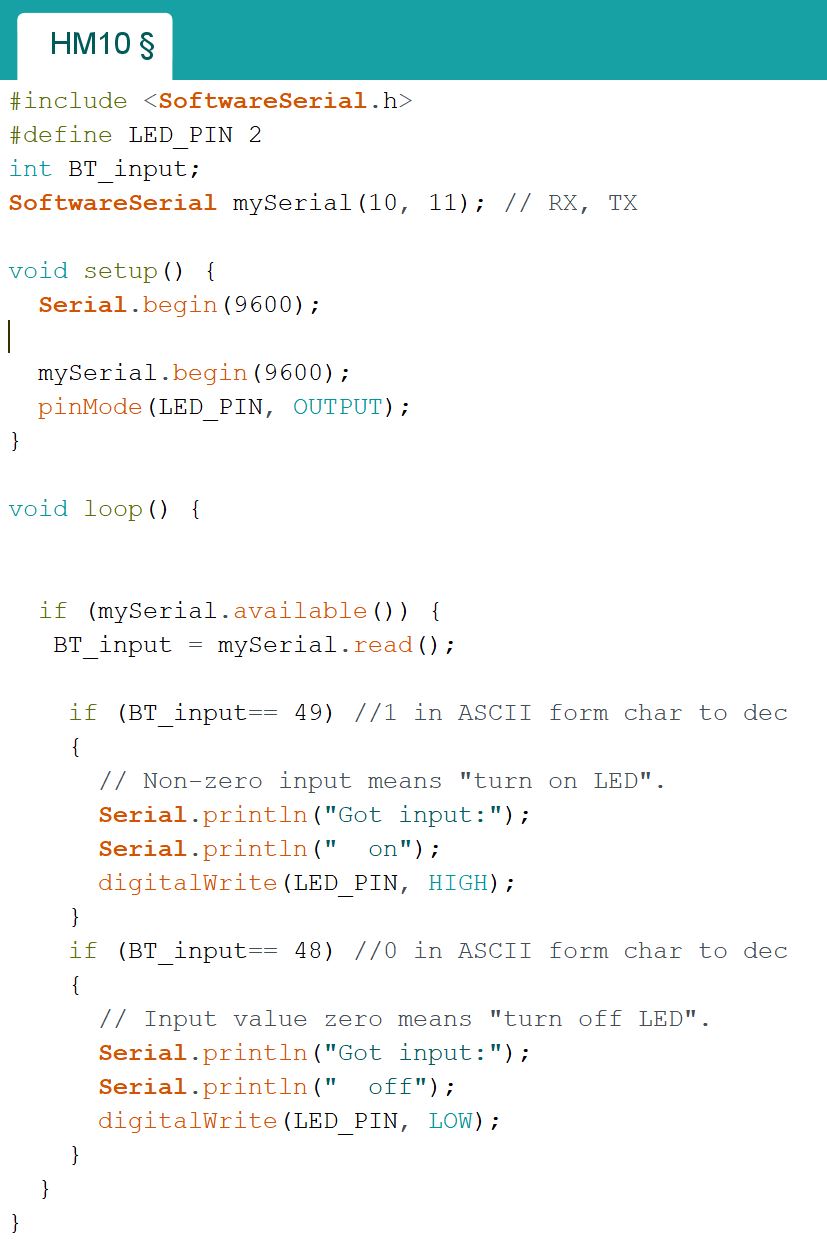

The team successfully tested the HM 10 BLE module by connecting it to the Arduino and wrote a simple code to turn an LED on and off. Using an existing App called "HM10 Bluetooth Serial Lite", we were able to connect the BLE module to the app. The app allowed us to send information by typing messages like 0 or 1. We then wrote an Arduino code to receive the signal from the BLE module and print a message to the serial monitor and turn the LED on if signal received is 1 and turns it off if zero.

Controls Team:

The team successfully tested the HM 10 BLE module by connecting it to the Arduino and wrote a simple code to turn an LED on and off. Using an existing App called "HM10 Bluetooth Serial Lite", we were able to connect the BLE module to the app. The app allowed us to send information by typing messages like 0 or 1. We then wrote an Arduino code to receive the signal from the BLE module and print a message to the serial monitor and turn the LED on if signal received is 1 and turns it off if zero.

Figure 1: HM 10 Arduino Code

Written by:

Asmaa Darwish

The Guideway Team:

The Guideway Team has been modifying the CAD model of the track to implement new designs. We are adding dowel pins to have accurate alignment between the guideway pieces.

The team as a Whole

We prepared a short presentation for the Podcar City Conference. Julio represented our team and presented the main goal of our team as well as our design choices for the track, bogie, and controls.

Progress for this week:

The controls team is researching how to connect the HM 10 to our app. We are looking at Swift tutorials to understand how BLE works and how it can be connected to the iPhone. The Guideway team will continue modifying the CAD model of the track.

Written by:

Asmaa Darwish

Comments

Post a Comment